MARINFLEX anti vibration marine mounts are devices designed to reduce vibrations and noise, optimised for low rotation speeds. With a bell-shaped structure made of natural rubber with a specific compound and galvanised steel, it offers excellent absorption and resistance. Ideal for low-speed motors, industrial machinery and mechanical systems, it guarantees stability and durability. Available in different hardnesses, it adapts to various needs, ensuring reliable performance in a compact and robust design.

MARINFLEX bell-shaped anti-vibration mounts are specialised devices designed to reduce vibrations and noise generated by low-speed rotating machinery, both in marine and industrial applications. Their bell-shaped structure ensures optimal isolation from oscillations, offering stability and protection for equipment and support surfaces. Made from high-quality materials, these mounts are perfect for applications that require precise vibration control at low speeds.

Benefits

Choosing MARINFLEX mounts means relying on a targeted solution for machinery operating at low speeds, ensuring excellent and long-lasting performance. Their specific design allows them to effectively absorb vibrations even at low frequencies, improving operational precision and reducing equipment wear. Easy to install and highly resistant, these mounts offer a reliable and convenient solution. Other MARINFLEX models will be described on other pages.

Principal characteristics

MARINFLEX mounts are made with a corrosion-resistant steel bell and a specially formulated rubber anti-vibration element to optimise low-frequency vibration absorption. Their robust construction ensures even weight distribution and superior stability, even under moderate loads. Resistant to salt water, oils, chemicals and extreme temperatures, they are available in different configurations to suit specific operational requirements.

Applications

These mounts are ideal for marine applications, such as auxiliary engines, low-speed pumps and ventilation systems on boats, where low-speed vibration control is essential for comfort and efficiency. In industrial applications, they are used in machinery such as compressors, fans and low-speed processing equipment. Thanks to their versatility, they are perfect for sectors such as shipbuilding, food processing and energy, improving the safety and longevity of equipment.

Download PDF catalogue for MARINFLEX anti vibration marine mounts:

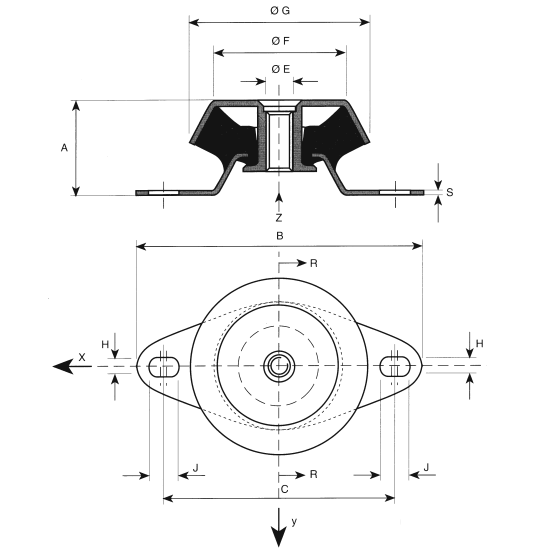

| Rif. CF N. Norma | A | B | C | G | F | H | J | S | E | Load daN |

| MARIN 94393/45 | 35 | 106 | 82,5 | 60 | 38 | 8,3 | 16 | 2 | M10 | 975 |

| MARIN 94394/45 | 35 | 106 | 82,5 | 60 | 38 | 8,3 | 16 | 2 | M12 | 975 |

| MARIN 94395/45 | 31 | 106 | 82,5 | 60 | 50 | 8,3 | 16 | 3 | M10 | 1600 |

| MARIN 94396/45 | 31 | 106 | 82,5 | 60 | 50 | 8,3 | 16 | 3 | M12 | 1600 |

| MARIN 94397/45 | 30 | 128 | 110 | 77 | 59 | 9 | 9 | 2 | M10 | 1250 |

| MARIN 94398/45 | 35 | 128 | 110 | 82 | 60 | 11 | 11 | 2 | M10 | 3000 |

| MARIN 94399/45 | 45 | 128 | 110 | 92 | 73,5 | 10,5 | 10,5 | 3 | M12 | 3500 |

| MARIN 94400/45 | 35 | 144 | 124 | 93 | 70 | 10 | 10 | 2,5 | M10 | 1800 |

| MARIN 94401/45 | 38 | 172 | 142 | 106 | 81 | 14 | 18 | 3 | M12 | 2800 |

| MARIN 94402/45 | 38 | 172 | 142 | 106 | 81 | 14 | 18 | 3 | M16 | 2800 |

| MARIN 94403/45 | 50 | 190 | 160 | 108 | 83 | 16,5 | 16,5 | 5 | M14 | 4000 |

| MARIN 94404/45 | 50 | 190 | 160 | 108 | 83 | 16.5 | 16,5 | 5 | M16 | 5000 |

| MARIN 94405/45 | 42 | 188 | 158 | 121 | 92 | 13,5 | 13,5 | 3 | M16 | 4000 |

| MARIN 94406/45 | 48 | 216 | 182,5 | 144 | 121 | 14 | 18 | 4 | M16 | 4250 |

| MARIN 94393/55 | 35 | 106 | 82,5 | 60 | 38 | 8,3 | 16 | 2 | M10 | 1400 |

| MARIN 94394/55 | 35 | 106 | 82,5 | 60 | 38 | 8.3 | 16 | 2 | M12 | 1400 |

| MARIN 94395/55 | 31 | 106 | 82,5 | 60 | 50 | 8.3. | 16 | 3 | M10 | 2400 |

| MARIN 94396/55 | 31 | 106 | 82,5 | 60 | 50 | 8,3 | 16 | 3 | M12 | 2400 |

| MARIN 94397/55 | 30 | 128 | 110 | 77 | 59 | 9 | 9 | 2 | M10 | 2000 |

| MARIN 94398/55 | 35 | 128 | 110 | 82 | 60 | 11 | 11 | 2 | M10 | 4000 |

| MARIN 94399/55 | 45 | 128 | 110 | 92 | 73,5 | 10,5 | 10,5 | 3 | M12 | 5000 |

| MARIN 94400/55 | 35 | 144 | 124 | 93 | 70 | 10 | 10 | 2,5 | M10 | 2900 |

| MARIN 94401/55 | 38 | 172 | 142 | 106 | 81 | 14 | 18 | 3 | M12 | 4000 |

| MARIN 94402/55 | 38 | 172 | 142 | 106 | 81 | 14 | 18 | 3 | M16 | 4000 |

| MARIN 94403/55 | 50 | 190 | 160 | 108 | 83 | 16,5 | 16,5 | 5 | M14 | 7000 |

| MARIN 94404/55 | 50 | 190 | 160 | 108 | 83 | 16,5 | 16,5 | 5 | M16 | 7000 |

| MARIN 94405/55 | 42 | 188 | 158 | 121 | 92 | 13,5 | 13,5 | 3 | M16 | 6000 |

| MARIN 94406/55 | 48 | 216 | 182,5 | 144 | 121 | 14 | 18 | 4 | M16 | 6250 |

| MARIN 94393/65 | 35 | 106 | 82,5 | 60 | 38 | 8,3 | 16 | 2 | M10 | 1700 |

| MARIN 94394/65 | 35 | 106 | 82,5 | 60 | 38 | 8,3 | 16 | 2 | M12 | 1700 |

| MARIN 94395/65 | 31 | 106 | 82,5 | 60 | 50 | 8,3 | 16 | 3 | M10 | 3000 |

| MARIN 94396/65 | 31 | 106 | 82,5 | 60 | 50 | 8.3 | 16 | 3 | M12 | 3000 |

| MARIN 94397/65 | 30 | 128 | 110 | 77 | 59 | 9 | 9 | 2 | M10 | 2800 |

| MARIN 94398/65 | 35 | 128 | 110 | 82 | 60 | 11 | 11 | 2 | M10 | 4500 |

| MARIN 94399/65 | 45 | 128 | 110 | 92 | 73.5 | 10,5 | 10,5 | 3 | M12 | 6000 |

| MARIN 94400/65 | 35 | 144 | 124 | 93 | 70 | 10 | 10 | 2.5 | M10 | 4000 |

| MARIN 94401/65 | 38 | 172 | 142 | 106 | 81 | 14 | 18 | 3 | M12 | 5000 |

| MARIN 94402/65 | 38 | 172 | 142 | 106 | 81 | 14 | 18 | 3 | M16 | 5000 |

| MARIN 94403/65 | 50 | 190 | 160 | 108 | 83 | 16,5 | 16,5 | 5 | M14 | 8500 |

| MARIN 94404/65 | 50 | 190 | 160 | 108 | 83 | 16,5 | 16,5 | 5 | M16 | 9000 |

| MARIN 94405/65 | 42 | 188 | 158 | 121 | 92 | 13,5 | 13,5 | 3 | M16 | 7000 |

| MARIN 94406/65 | 48 | 216 | 182,5 | 144 | 121 | 14 | 18 | 4 | M16 | 7250 |

| MARIN 94500/45 | 50 | 180 | 150 | 108 | 83 | 16,5 | 16,5 | 6 | M16 | 5000 |

| MARIN 94500/55 | 50 | 180 | 150 | 108 | 83 | 16,5 | 16,5 | 6 | M16 | 7000 |

| MARIN 94500/65 | 50 | 180 | 150 | 108 | 83 | 16,5 | 16,5 | 6 | M16 | 9000 |

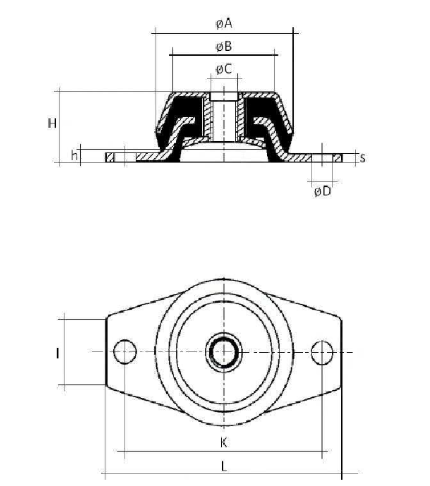

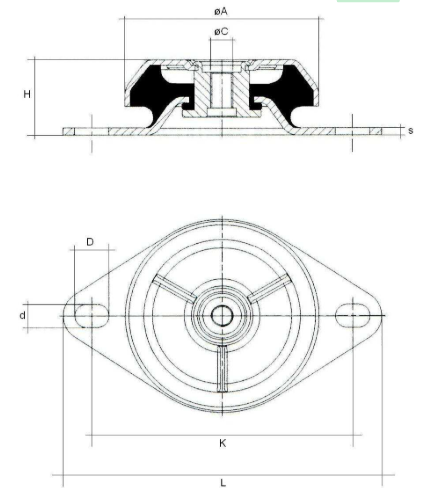

| Article | øA | øB | øC | øD | H | h | s | K | L | I | Load max daN |

| Marin 94504/65 | 108 | 83 | 20 | 16,5 | 50 | 9 | 6 | 150 | 180 | 49 | 3750 |

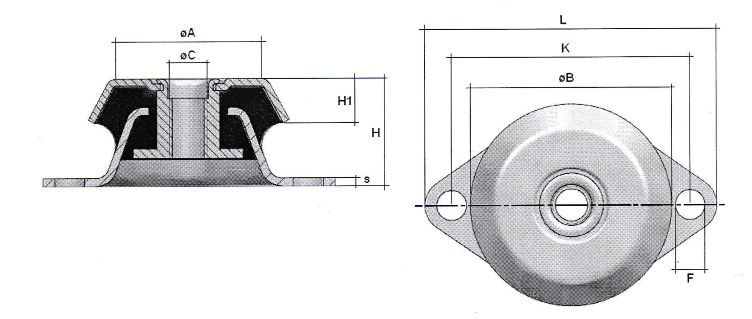

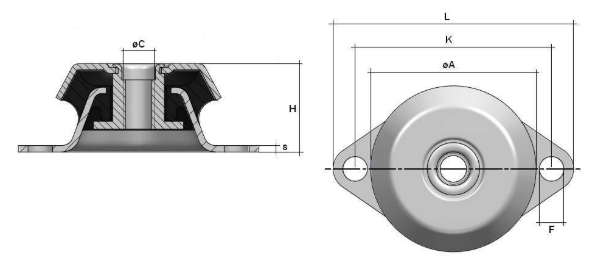

| Article | øA | øB | øC | K | L | H | H1 | s | F | Load (Kg) |

| 687634/1 | 47 | 64 | M12 | 76 | 93 | 34 | 14 | 2,5 | 9,5 | 50 |

| 687634/2 | 47 | 64 | M12 | 76 | 93 | 34 | 14 | 2,5 | 9,5 | 70 |

| 687634/3 | 47 | 64 | M12 | 76 | 93 | 34 | 14 | 2,5 | 9,5 | 105 |

| 687634/4 | 47 | 64 | M12 | 76 | 93 | 34 | 14 | 2,5 | 9,5 | 130 |

Marinflex Type B is available on request

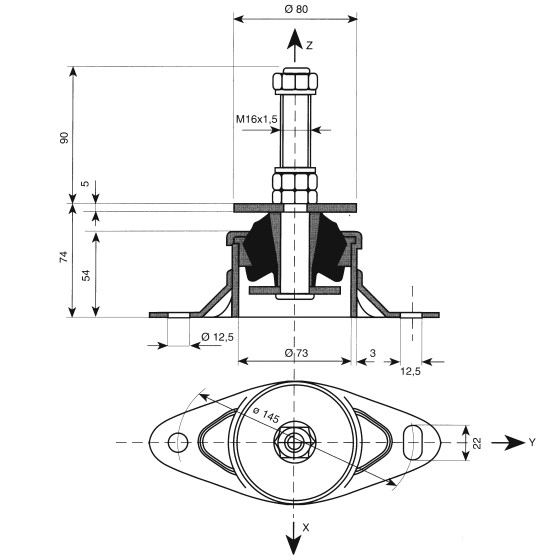

Pirelli 92695 MARINFLEX TYPE ‘B’

Hardness: 65 (shore)

Axial load: 2000 (N)

Axial stiffness: 420 (N/mm)

Axial natural frequency: 7.25 (Hz)

Lateral stiffness: 1000 (N/mm)

Lateral natural frequency with axial load: 11 (Hz)

Tightening torque: 70 (Nm)

| Article | øA | H | øC | K | L | s | F | Durezza(Sh) | Load(daN) |

| 516334/45 | 63 | 34 | M12 | 76 | 93 | 2 | 9,5 | 45 | 70 |

| 516334/60 | 63 | 34 | M12 | 76 | 93 | 2 | 9,5 | 60 | 110 |

| 516334/70 | 63 | 34 | M12 | 76 | 93 | 2 | 9,5 | 70 | 130 |

| Article | A | H | øC | dxD | K | L | s | Load max [daN] 45sh | Load max [daN] 60sh |

| 5163361 | 63 | 36 | M10 | 11×15 | 100 | 120 | 2,5 | 60,0 | 120,0 |

| 5163351 | 63 | 35 | M10 | 9×12 | 88 | 110 | 2 | 30,0 | 60,0 |

| 5183351 | 83 | 35 | M10 | 11,5×15 | 110 | 135 | 3 | 80,0 | 180,0 |

| 5183352 | 83 | 35 | M12 | 11,5×15 | 110 | 135 | 3 | 80,0 | 180,0 |

| 5110642 | 106 | 42 | M12 | 13×19 | 143 | 175 | 4 | 167,0 | 335,0 |

Order anti-vibration mounts in different variants and sizes for your applications:

Contact our team for tailored advice on your project. Larosi offers a wide range of vibration dampers with same-day shipping throughout Europe. Discover our advantages now!