Hollow Rubber Springs: Effectively managing mechanical vibration

Hollow rubber springs represent a cutting-edge solution for modern engineering, designed to excel in shock absorption and isolated vibration management. Made from high-quality vulcanised natural rubber, these springs stand out for their exceptional insulation capacity and progressive stiffness, which ensures long deflection and high load capacity.

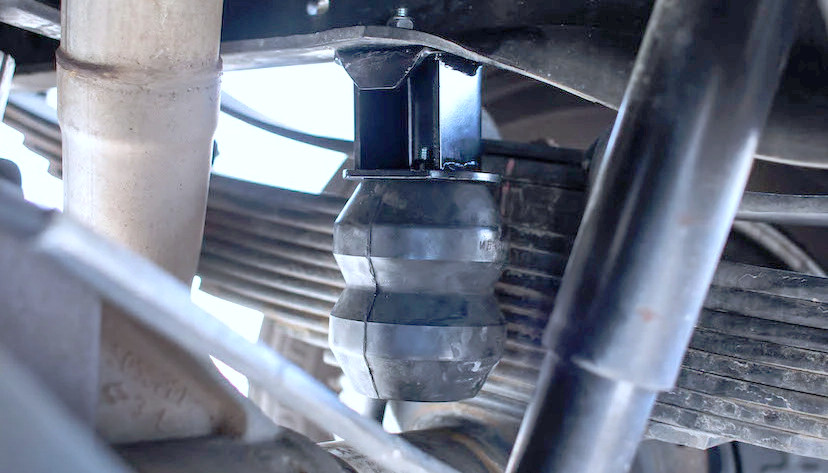

Thanks to their robust construction and intelligent design, Hollow rubber springs are maintenance-free and require limited mounting space, making them a practical and efficient choice for numerous industrial applications.

Compression springs, rubber shock absorbers

Product name: compression springs, rubber shock absorbers, perforated cylindrical buffers, hollow rubber springs, perforated rubber springs.

- Material: NBR/NR/EPDM or other rubber

- Dimensions: standard plus customised on request

- Colour: black

- Certification: ISO9001, SGS, ROHS

- Function: Shock absorber, bumper, anti-vibration spring for industry and machinery.

- Hardness: 50-70 Shores A

Shape:

- Cylinder

- Barrel

- Hourglass

Some describe their shapes as rubber bullets or pumpkin-shaped.

Hollow rubber springs function as a vibration isolator and shock absorber. It is designed to solve the low strength and poor load-bearing capacity of existing rubber shear springs.

The main body of the shear spring is made of non-metallic elastic materials, with a cylinder of holes in the middle.

Main advantages: easy to install, reliable and long-lasting, highly elastic.

The versatility of Hollow rubber springs makes them indispensable in a wide range of sectors, from automotive to mechanical engineering. They are commonly used in applications that require precise management of load and vibration dynamics, such as in vibrating tables, vibrating separators, centrifuges and metalworking machinery. Their effectiveness in withstanding exceptional deformation also makes them perfect for use on heavy machinery and trailers, ensuring reliable performance and longer component life.

MAIN FEATURES

Made from high-quality vulcanised natural rubber, Hollow rubber springs are designed to absorb shocks and isolated vibrations. Their main features are:

- High insulation capacity;

- Long deflection and high load capacity;

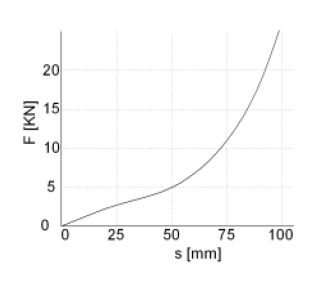

- Progressive spring stiffness;

- Limited installation space required;

- Maintenance-free.

These springs are commonly used in automotive and mechanical engineering for vibrating tables, vibrating separators, centrifuges, punching die extractors, heavy-duty machinery and trailers.

These products are mainly used in compression on the X-axis.

Hollow rubber springs can withstand exceptional deformations of up to 70% of their height. For deformation constants, see the data sheet for each product.