Double and triple convoluted hollow rubber springs

Double and triple convoluted hollow rubber springs (hourglass-shaped) are special components designed to operate in more complex conditions than standard barrel springs. Their unique hourglass shape provides greater flexibility in compression and flexion. This design allows the spring not only to effectively absorb shocks and vibrations on the axle, but also to compensate for lateral (radial) loads. The two- or three-section variants allow for even more precise adjustment of stiffness and deformation characteristics, making them indispensable in complex mechanisms. These springs are used where multi-axis damping is required, such as in industrial equipment, transport, agricultural machinery and even robotics.

The main advantage of these springs is their multifunctionality. The hourglass shape ensures a more progressive energy absorption characteristic than barrel springs, allowing them to handle different types of loads simultaneously. They are capable of damping not only vertical impacts, but also compensating for horizontal displacements and torques. This significantly reduces the load on other components of the system and extends its service life. Like other rubber springs, they are durable, maintenance-free, corrosion-resistant and operate quietly, making them the ideal choice for complex and critical tasks.

Double and triple convoluted hollow rubber springs range

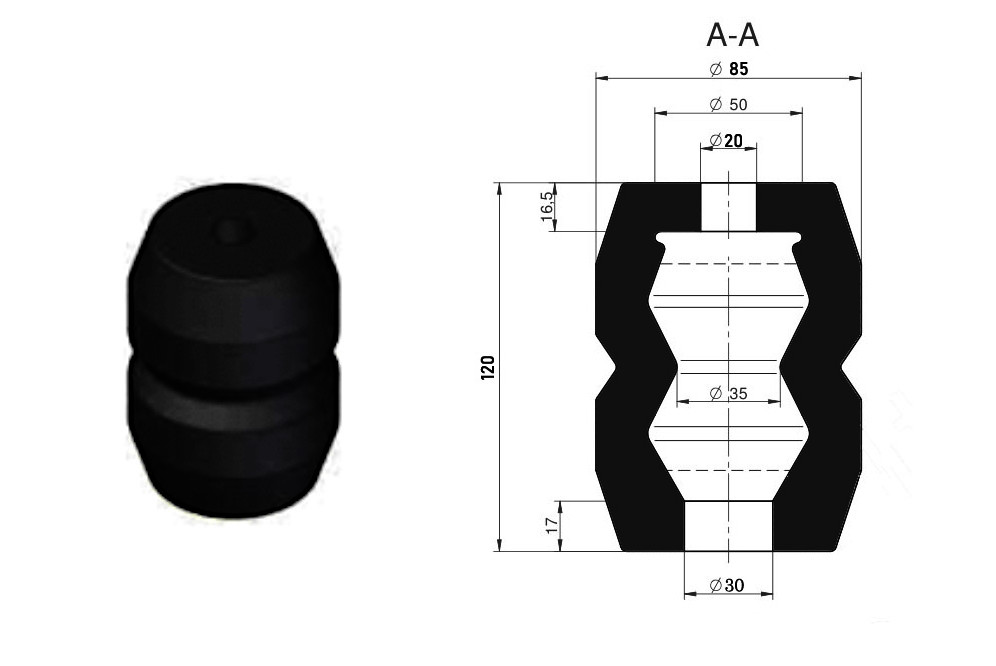

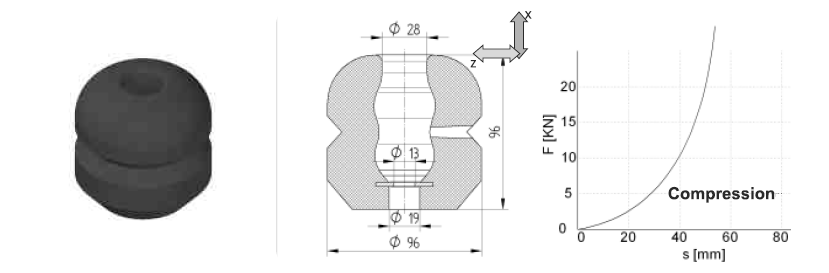

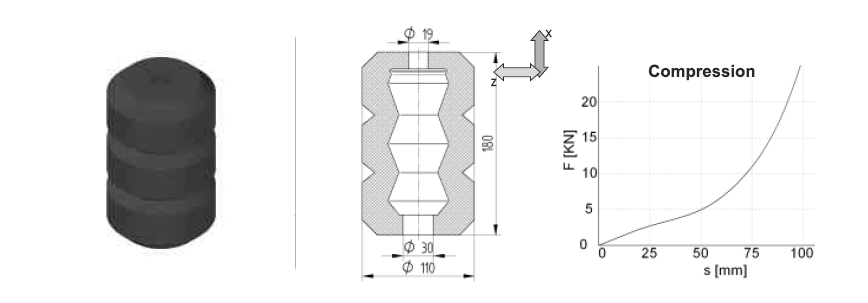

Code: 39309

Opposing force values:

29,5 mm – 2500 N

54,5 mm – 5000 N

67 mm – 8000 N

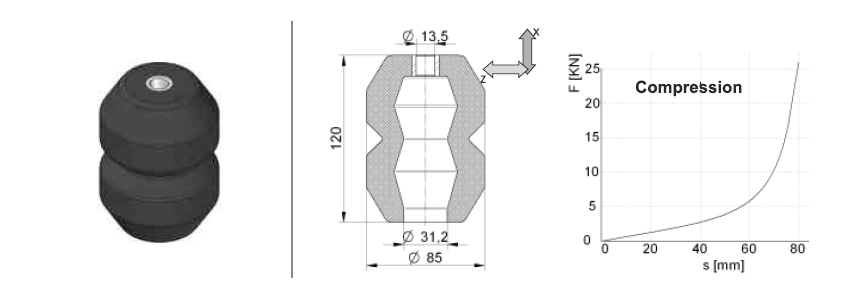

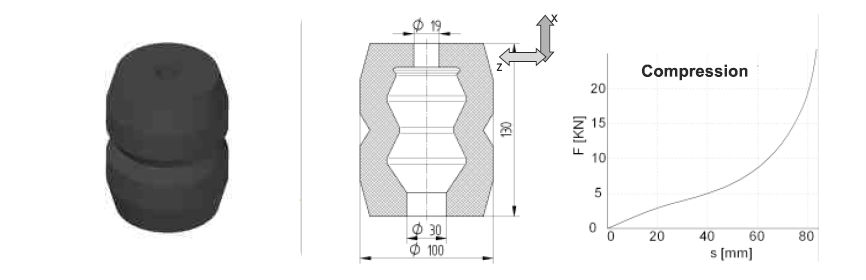

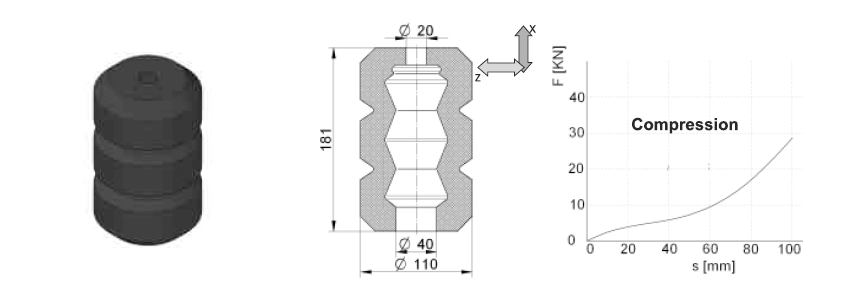

Code: 39309/2

Recommended deformation constant on the X axis (max mm.): 40

Opposing force values:

20 mm – 1630 N

40 mm – 2860 N

60 mm – 5500 N

80 mm – 26050 N

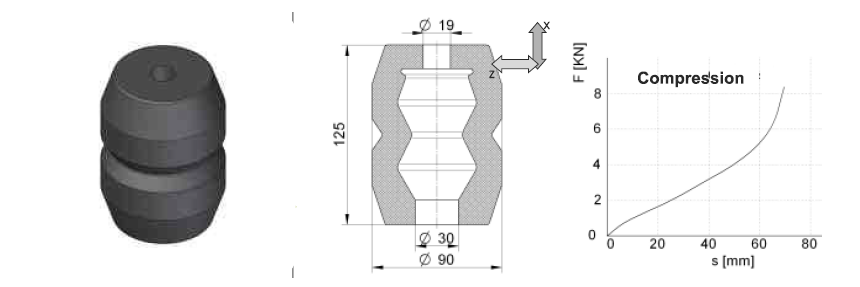

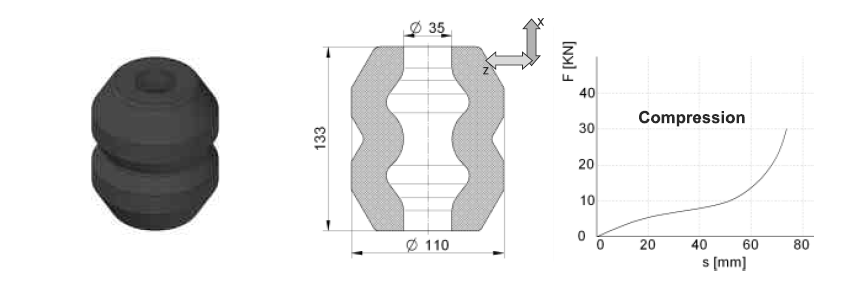

Code: 86771

Costante di deformazione consigliata sull’asse X (max mm.): 44

Opposing force values:

10 mm – 1070 N

25 mm – 2140 N

44 mm – 3400 N

65 mm – 6490 N

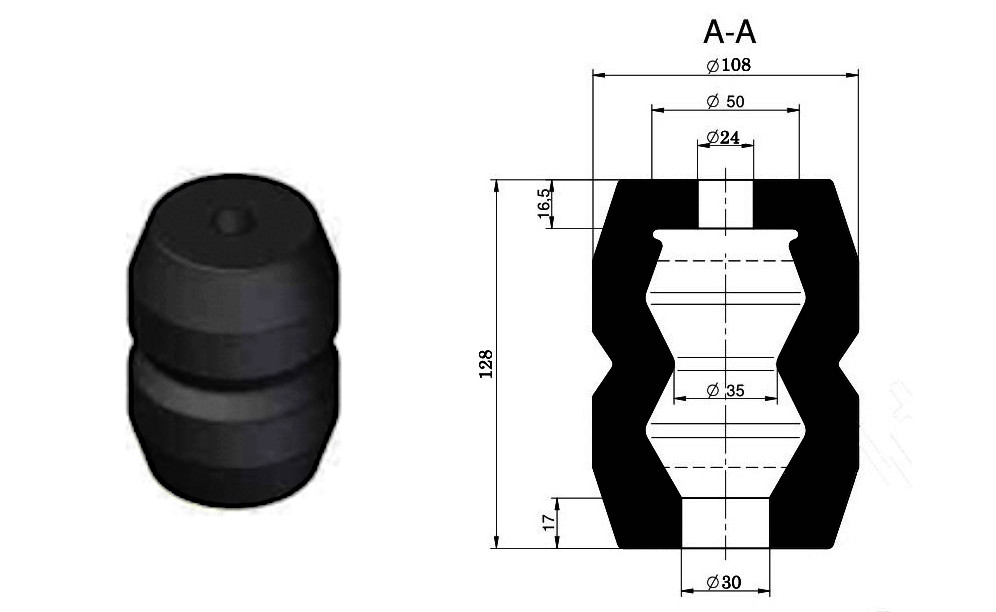

Code: 89404

Recommended deformation constant on the X axis (max mm.): 25

Opposing force values:

15 mm – 3100 N

25 mm – 5430 N

35 mm – 8450 N

Code: 39548/2

Recommended deformation constant on the X axis (max mm.): 45

Opposing force values:

15 mm – 2120 N

30 mm – 3760 N

45 mm – 5680 N

60 mm – 8650 N

Code: 39648/2

Recommended deformation constant on the X axis (max mm.): 45

Opposing force values:

15 mm – 2960 N

30 mm – 5300 N

45 mm – 7350 N

60 mm – 11900 N

Code: 80128

Opposing force values:

29,5 mm – 2500 N

54,5 mm – 5000 N

67 mm – 8000 N

Code: 37234

Recommended deformation constant on the X axis (max mm.): 70

Opposing force values:

20 mm – 2100 N

40 mm – 4000 N

60 mm – 7300 N

90 mm – 19200 N

Code: 37334

Recommended deformation constant on the X axis (max mm.): 70

Opposing force values:

20 mm – 2940 N

40 mm – 5020 N

60 mm – 9200 N

90 mm – 22100 N

You can order spare parts from us in the required dimensions and format. Contact our specialists.