Table of Contents

It is impotant to have a deep understanding of loop couplers applications and functions in order to choose best components for your task. This article covers these topics and helps to find appropriate supplies.

1. What an Elastic Coupling Is and Its Structural Function

An elastic shaft coupler is a crucial mechanical component designed to flexibly connect two rotating shafts — typically a drive shaft and the shaft of a driven component (e.g., a pump, gearbox, or compressor). Its primary function is two-fold: to transmit driving torque efficiently and, at the same time, compensate for both dynamic and static misalignments between the shafts, as well as to dampen shocks and vibrations arising during operation.

Unlike a rigid coupling, an elastic coupler introduces a controlled flexibility element into the powertrain. This element — often made of elastomeric material (rubber, polyurethane, etc.) — allows shafts to operate even when not perfectly aligned or under sudden loads, providing greater operational tolerance and better protection of the entire machine.

2. Main Functions: The Importance of the Dynamic Role

Elastic couplings perform functions that go far beyond simple mechanical joining and act as genuine safety and optimization components in the system:

• Reliable Torque Transmission:

They ensure continuous and stable transfer of power from the motor to the load. Their design aims to minimize backlash (angular play) for as precise motion transmission as possible, especially in servo-assisted systems.

• Misalignment Compensation:

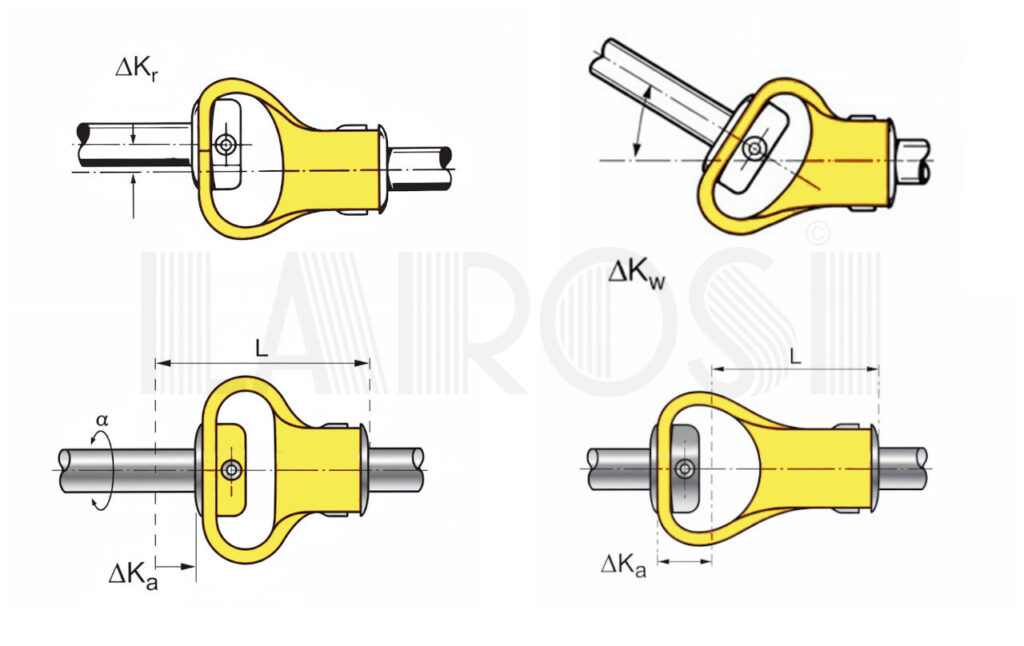

- Angular misalignment: when shafts are not parallel and form a small angle.

- Radial/parallel misalignment: when shaft axes are parallel but not perfectly coaxial.

- Axial displacement: allows a small relative movement along the rotation axis, often due to thermal expansion or axial play of bearings.

• Vibration and Shock Damping:

The elastic element acts like a shock absorber, dampening torsional vibrations generated by the motor or load and reducing dynamic forces transmitted to other components, significantly extending the life of bearings, seals, and gear housings.

• Isolation and Protection:

- Electrical Isolation: Many versions provide dielectric isolation between metal hubs, preventing stray currents that can damage bearings (e.g., in inverter drives).

- Overload Protection: In case of excessive torque, some couplings are designed to fail in a controlled way (e.g., break or slip of the elastic element), acting as a “mechanical fuse” to prevent catastrophic damage to more expensive components (motor or driven machine).

3. Key Technical Characteristics for Selection

Proper selection of a coupling requires analysis of specific technical properties that determine its suitability and durability in an industrial application:

• Torsional Stiffness and Backlash:

A fundamental balance. The coupling must be rigid enough to transmit torque with precision (reduced or zero backlash) but sufficiently elastic to damp vibrations. Stiffness is often defined by the Shore hardness of the elastomer.

• Low Restoring Forces:

Crucial for compensation effectiveness. An ideal coupler should correct misalignment without generating excessive radial or axial forces that would overload support bearings and negate the benefits of flexibility.

• No Sliding Parts and Maintenance Needs:

Many elastic couplings (jaw, star, toothed, etc.) have no parts requiring lubrication or adjustment. This translates into low wear, reduced maintenance, and cleaner operation — a significant advantage for total cost of ownership (TCO).

• Materials and Chemical/Thermal Resistance:

The elastic element (often polyurethane, Hytrel, or special rubber) must be compatible with the operating environment, resist oils, solvents, detergents, moisture, and operate across a wide temperature range without losing elastic and mechanical properties.

• Maximum Misalignment Capacity:

Each coupling has specific compensation limits for radial, axial, and angular misalignment. Respecting these limits is vital to prevent premature fatigue of the elastic element and consequent failure.

4. Application Areas: Versatility Across Industries

Understanding the applications and functions of loop couplers reveals their indispensability in virtually every industrial field. These standard components are ideal in almost all sectors due to their ability to adapt to varied power, speed, and environmental requirements, ensuring reliable coupling performance:

• General Machinery and Pumps/Compressors:

Widely used as couplings between electric motors and centrifugal pumps, piston compressors, industrial fans, and mixers. Their primary role here is to absorb vibrations and compensate frequent operational misalignments.

• Industrial Automation and Machine Tools:

In applications requiring very high precision, such as servo motor systems or positioning, couplings for encoders and stepper motors are used. These are often zero-backlash to ensure maximum fidelity and motion accuracy.

• Food, Chemical, and Pharmaceutical Sectors:

Hygienic design couplings and materials (such as stainless steel hubs and special elastomers) offer resistance to aggressive washdown cycles (CIP/SIP) and chemical detergents.

• Heavy Drives and Conveyors:

In these power chains, couplings with high torque capacity and robust shock and inertia absorption are preferred.

• Generators and Power Units:

Used to effectively isolate combustion engine vibrations, protecting both the generator and surrounding structure from unwanted stresses.

5. Benefits of Use: Economic and Operational Advantages

Targeted adoption of an elastic coupler yields tangible benefits in efficiency, reliability, and operating costs in any plant. The functions and applications of elastic couplings translate directly into the following advantages:

• Reliability and Component Life:

The greatest advantage is reduced mechanical stress on bearings, seals, and adjacent shafts. By damping vibrations and misalignment forces, the coupler dramatically extends the mean time between failures (MTBF).

• Reduced Maintenance Costs and Downtime:

Thanks to automatic compensation of errors and the maintenance-free nature of many models, realignment interventions and premature replacement of expensive spares are reduced, especially when used as a coupling for electric motors where maintenance is always a priority.

• Installation Flexibility and Rapid Assembly:

The ability to tolerate misalignment simplifies initial installation; “micron-level” alignment is not required, enabling faster assembly and greater tolerance to structural settling after installation.

• Anti-Shock Protection and Investment Safeguarding:

The mechanical fuse and torque absorber function protects the heart of the system (the motor) and the load (the driven machine) from irreparable damage in case of abnormal torque spikes or sudden locks.

• Effective Power Transmission:

Latest-generation solutions ensure high-efficiency torque transmission, reducing energy losses typical of overly compliant couplings.

6. When to Choose an Elastic Coupler: Decision Criteria

The decision to use an elastic coupler instead of a rigid or other type of shaft coupling is based on specific operational and design conditions:

- Presence of significant misalignments that a rigid coupling cannot tolerate without generating destructive forces.

- Need for damping in the presence of high torsional vibrations or shock loads.

- Low maintenance and long life requirements.

- Requirement for electrical or thermal isolation between shafts.

- Priority on positioning precision while maintaining compensation capability.

7. Classification: Common Types of Elastic Couplings

The term “elastic coupling” actually covers several technologies, each optimized for specific conditions:

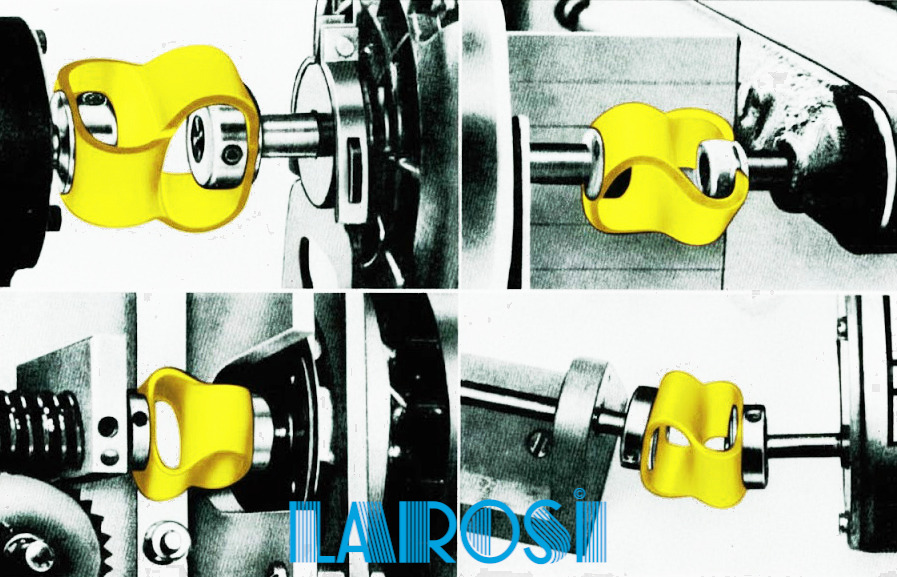

• Jaw (Spider) Couplings: Use an elastomeric star element between two jaw hubs, offering good damping, minimal backlash, and easy replacement of the elastic element.

• Tyre (Tire) Couplings: Use a toroidal rubber element screwed to hubs, excelling in compensating large radial and angular misalignments.

• Torsional Couplings (HRC, etc.): Designed for high torque peaks and torsional vibration absorption.

• Pin and Bushing Couplings: Use metal pins connecting plates with elastic bushings, suitable for medium and high torque applications.

8. Limits and Advanced Design Considerations

Although elastic couplings offer great versatility, careful design is essential to fully exploit their benefits and avoid limitations:

- Selecting the Elastic Material: Shore hardness directly influences torsional stiffness and damping capacity.

- Critical Speed and Dynamics: At very high rotational speeds, even a well-balanced coupling can generate vibrations.

- Environmental Conditions Impact: Elastomer life is reduced by extreme temperatures, ozone or UV exposure, and contact with incompatible chemicals.

- Proper Sizing: Couplings must be sized not only to nominal torque but also peak torques and the service factor imposed by the type of load.

9. Conclusions

Elastic shaft couplings are much more than simple connectors: they are precision engineering components that ensure the operational health and longevity of entire powertrain systems. An in-depth analysis of the functions and applications of Paguflex elastic couplings clearly shows that their ability to transmit torque, compensate inevitable misalignments, and dampen vibrations makes them indispensable in modern industry. In contexts where reliability and reduced operating costs are critical factors, selecting the right coupler directly invests in operational continuity and reduced extraordinary maintenance.

For optimal selection in terms of material, dimensions, and type for your specific application, we invite you to consult our technical experts.

Learn more about Paguflex

Material and Specifications of Elastic Shaft Couplings

How to Choose a Plastic Flexible Coupling

Origin, Evolution, and Warranty of the Registered Trademark PAGUAG PAGUFLEX

New Paguflex Counter Displays