Cone bearing for vehicle cabins with square base is a device designed to reduce vibrations and noise, with a conical shape and a solid square base. Made of natural rubber and galvanized steel, it offers excellent strength and stability. Ideal for cabinets, industrial machinery, and heavy systems, it ensures secure and durable fastening. Available in different hardnesses, it adapts to various applications, ensuring optimal performance in a robust and compact design.

This advanced device was designed to reduce vibrations and stresses in industrial and mechanical applications. Featuring a high-strength rubber conical structure and a square metal base, this mount provides excellent stability and shock absorption. The square base offers a solid anchorage, making it ideal for machinery and vehicles that require robust support in dynamic environments.

Benefits

Choosing our conical anti-vibration mounts with square bases means choosing a product that combines innovation and reliability. The square base ensures uniform load distribution, improving stability even under heavy stress. Made from top-quality materials, such as treated steel and custom rubber compounds, these mounts are resistant to wear, corrosion, and extreme environmental conditions. Our experience allows us to offer tailor-made solutions, ensuring optimal performance for every application.

Main features

The mount stands out for its ability to absorb axial and lateral vibrations, thanks to its conical shape and square base, which offers a larger contact surface. Available in different configurations, with stainless steel or galvanized steel and high-resilience rubber options, it is designed to withstand heavy loads and variable temperatures. The square base facilitates installation, ensuring a secure and stable fit. In addition, the design complies with strict safety standards, making it suitable for resistance tests such as “Rops Tests.”

Applications

This support is used in a wide range of sectors, including the automotive industry, agriculture, rail transport, and construction. It is particularly suitable for vibration isolation in driver cabs, heavy machinery engines, suspension systems, and ventilation systems. Its robustness and square base make it perfect for applications in harsh environments, such as excavators, tractors, cranes, and generators, where minimizing noise and vibration is essential to improve efficiency and safety.

Download PDF catalogue:

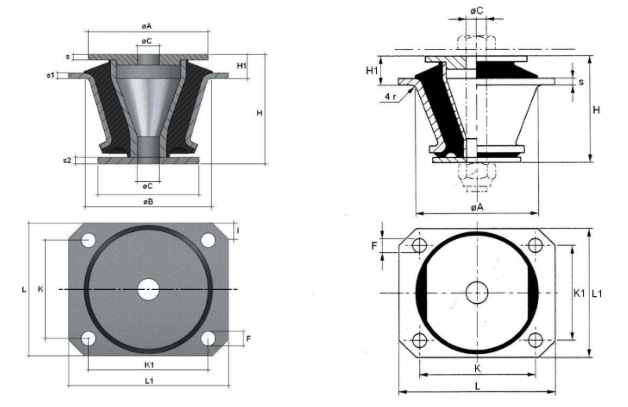

| Code | K | L | K1 | L1 | I | øA | øB | øC | H | H1 | F | s | s1 | s2 | Load (Kg) |

| 76165/45 | 74 | 100 | 90 | 120 | 12 | 90 | 95 | 16,5 | 82 | 18 | 11 | 4 | 4 | 5 | 400 |

| 76165/60 | 74 | 100 | 90 | 120 | 12 | 90 | 95 | 16,5 | 82 | 18 | 11 | 4 | 4 | 5 | 700 |

| 76165/70 | 74 | 100 | 90 | 120 | 12 | 90 | 95 | 16,5 | 82 | 18 | 11 | 4 | 4 | 5 | 1100 |

| 94377 | 109 | 140 | 112 | 120 | – | 109 | 109 | 20 | 95 | 23 | 11 | – | 4,5 | – | |

| 93819 | 90 | 120 | 74 | 100 | 93 | 70 | 16 | 72 | 20±0,5 | 11 | 5 | 4,3 | 4 |

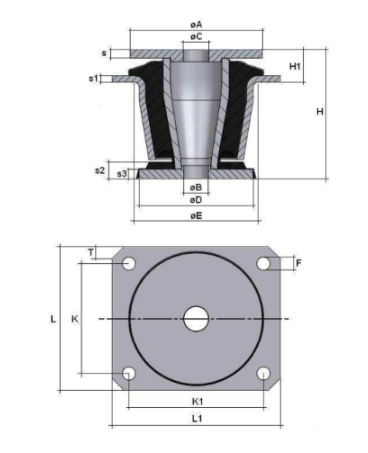

| Code | K | L | K1 | L1 | øA | øB | øC | øD | øE | H | H1 | F | s | s1 | s2 | s3 | T | Load (Kg) |

| 68952/45 | 92 | 120 | 112 | 140 | 110 | 20.5 | 21 | 95 | 103 | 107.5 | 27 | 11 | 7 | 5.5 | 14 | 8 | 10 | 500 |

| 68952/60 | 92 | 120 | 112 | 140 | 110 | 20.5 | 21 | 95 | 103 | 107.5 | 27 | 11 | 7 | 5.5 | 14 | 8 | 10 | 1100 |

| 68952/70 | 92 | 120 | 112 | 140 | 110 | 20.5 | 21 | 95 | 103 | 107.5 | 27 | 11 | 7 | 5.5 | 14 | 8 | 10 | 1560 |

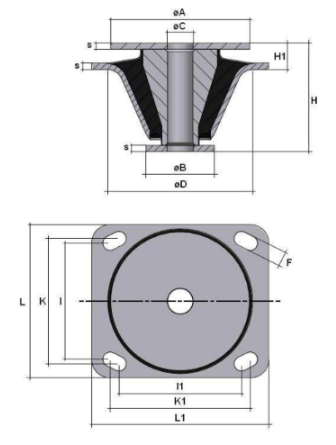

| Code | K | I | L | K1 | I1 | L1 | øA | øB | øC | øD | H | H1 | s | Load (Kg) |

| 68542/45 | 99 | 92 | 121 | 111 | 97 | 140 | 110 | 54 | 20.5 | 115 | 86 | 21 | 5 | 900 |

| 68542/60 | 99 | 92 | 121 | 111 | 97 | 140 | 110 | 54 | 20.5 | 115 | 86 | 21 | 5 | 1250 |

| 68542/70 | 99 | 92 | 121 | 111 | 97 | 140 | 110 | 54 | 20.5 | 115 | 86 | 21 | 5 | / |

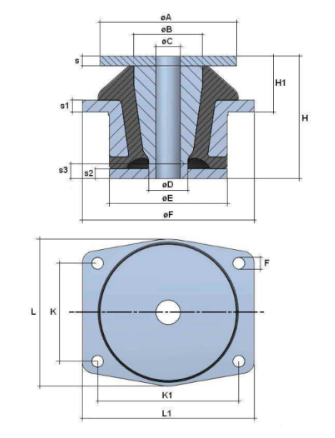

| Code | K | L | K1 | L1 | øA | øB | øC | øD | øE | øF | H | H1 | s | s1 | s2 | s3 | F | Load (Kg) |

| 68057/55 | 100 | 150 | 144 | 175 | 139 | 70 | 25 | 40 | 120 | 175 | 125 | 57 | 10 | 12 | 10 | 15 | 12 | 1750 |

| 68057/65 | 100 | 150 | 144 | 175 | 139 | 70 | 25 | 40 | 120 | 175 | 125 | 57 | 10 | 12 | 10 | 15 | 12 | 2000 |

| 68047/45 | 100±0.2 | 150±0.2 | 144±0.3 | 175±0.2 | 143 | 139 | 25 | 40 | 120 | 175 | 47 | 58 | 10 | 12 | 10 | 15 | 12±0.2 | 730 |

| 68047/55 | 100±0.2 | 150±0.2 | 144±0.3 | 175±0.2 | 143 | 139 | 25 | 40 | 120 | 175 | 47 | 58 | 10 | 12 | 10 | 15 | 12±0.2 | 120 |

You can order conical vibration mounts in different variants and sizes for your applications:

Our team is ready to offer you a tailor-made solution for your project. Larosi supplies a wide range of vibration mounts with fast shipping throughout Europe. Discover our services today!