Vibration Absorption: An Essential Introduction

Table of Contents

The importance of vibration absorption: Mechanical vibrations are oscillatory movements generated by mechanical systems such as motors, pumps, compressors, or industrial machinery. These movements, which are often unavoidable, occur when mechanical energy is transformed into oscillations that propagate through structures or components. Although they are a natural part of the operation of many types of equipment, mechanical vibrations pose a significant challenge in numerous sectors, from automotive to manufacturing, aerospace to agriculture.

Why are vibrations dangerous?

The answer lies in their effects: excessive noise, accelerated component wear, premature equipment failure, and potential health risks to operators, such as acoustic stress or injuries from prolonged vibrations.

In industrial environments, uncontrolled vibrations can compromise operational efficiency, increasing maintenance costs and reducing the lifespan of expensive machinery. For example, an engine that vibrates excessively can loosen bolts, damage bearings, or cause malfunctions in connected electronic systems. In addition, the noise generated can negatively affect worker comfort and productivity, making it essential to adopt vibration absorption solutions.

Vibration absorption is based on components designed to dissipate oscillatory energy, such as anti-vibration mounts, gaskets, and flexible couplings, made from materials such as rubber, silicone, or technoplastics such as PTFE and PA6. These elements, an integral part of many industrial applications, ensure greater stability and safety.

Expertise in the selection and application of these components is crucial to addressing vibration challenges, as demonstrated by the experience of companies specializing in industrial supplies. This guide will explore how vibration absorption protects machinery and operators, improving efficiency in various production contexts.

The Dangers of Uncontrolled Vibrations

Mechanical vibrations, if not properly controlled, pose a significant threat to machinery, workers, and production processes. One of the main dangers of vibrations is damage to equipment. Continuous oscillations can loosen bolts, cause fatigue in metal components, and accelerate wear on bearings, gears, and other critical parts. According to studies in the manufacturing sector, unmitigated vibrations are responsible for a significant percentage of machine downtime, with costs that can reach thousands of dollars per year for companies. For example, an industrial maintenance report highlights that 30% of mechanical failures in heavy machinery are attributable to uncontrolled vibrations, drastically reducing the useful life of equipment.

Another critical issue is noise pollution. Vibrations generate noise, often at levels that exceed occupational safety thresholds. This not only disturbs operators’ concentration, but can also cause long-term health problems, such as hearing loss or chronic stress. European regulations set strict limits for noise exposure, emphasizing the need to reduce vibrations to ensure safer and more comfortable working environments.

Safety risks are another concern. Uncontrolled vibrations can compromise the structural integrity of heavy machinery, leading to serious accidents, such as component failure or critical system malfunction. For example, in industries such as construction or aerospace, vibrations can destabilize equipment, increasing the risk of workplace accidents.

Finally, the economic impact of vibrations cannot be ignored. Vibration-induced wear increases maintenance and repair costs, while unexpected machine downtime interrupts production, causing financial losses. Investing in vibration absorption solutions, such as vibration isolators and seals, is therefore essential to protect business investments and ensure operational continuity. Mitigating these risks not only improves efficiency but also contributes to a safer and more productive work environment.

Download this article in PDF:

How Vibration Absorption Works

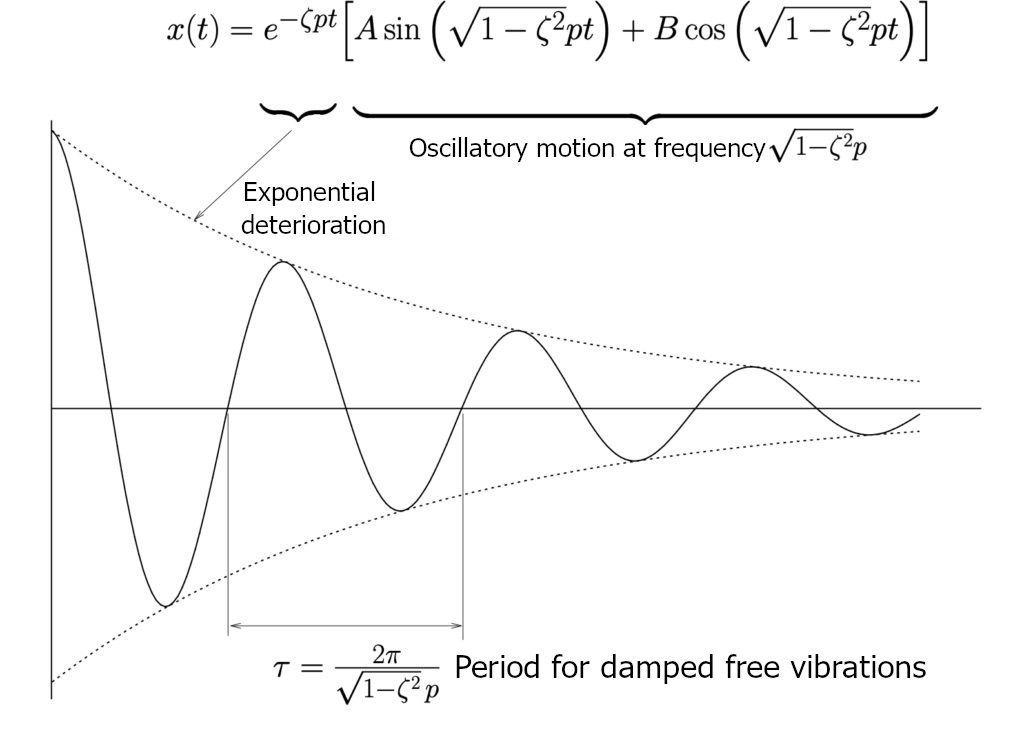

Vibration absorption is an essential technical process for protecting machinery and operators in numerous industrial sectors. This phenomenon is based on scientific principles such as viscoelasticity, the design of specific components, and the use of materials with targeted properties. Below, we will explore how anti-vibration solutions work, analyzing the physical mechanisms and characteristics of the components that make them effective.

Viscoelasticity: The Heart of Vibration Absorption

Viscoelasticity is the key property of materials such as rubber and neoprene, which allows them to absorb vibration energy. These materials combine elasticity (the ability to return to their original shape) and viscosity (the ability to dissipate energy through heat). When a machine vibrates, the oscillatory energy is transferred to the viscoelastic material, which temporarily deforms and converts part of this energy into heat through a process called hysteresis. Neoprene is particularly effective due to its ability to balance mechanical strength and energy damping, making it ideal for applications such as HVAC and automotive.

Common viscoelastic materials:

- Natural rubber (NR): High elasticity, ideal for light loads.

- Neoprene (CR): UV and oil resistant, perfect for outdoor environments.

- Silicone (VMQ): Suitable for high temperatures and medical applications.

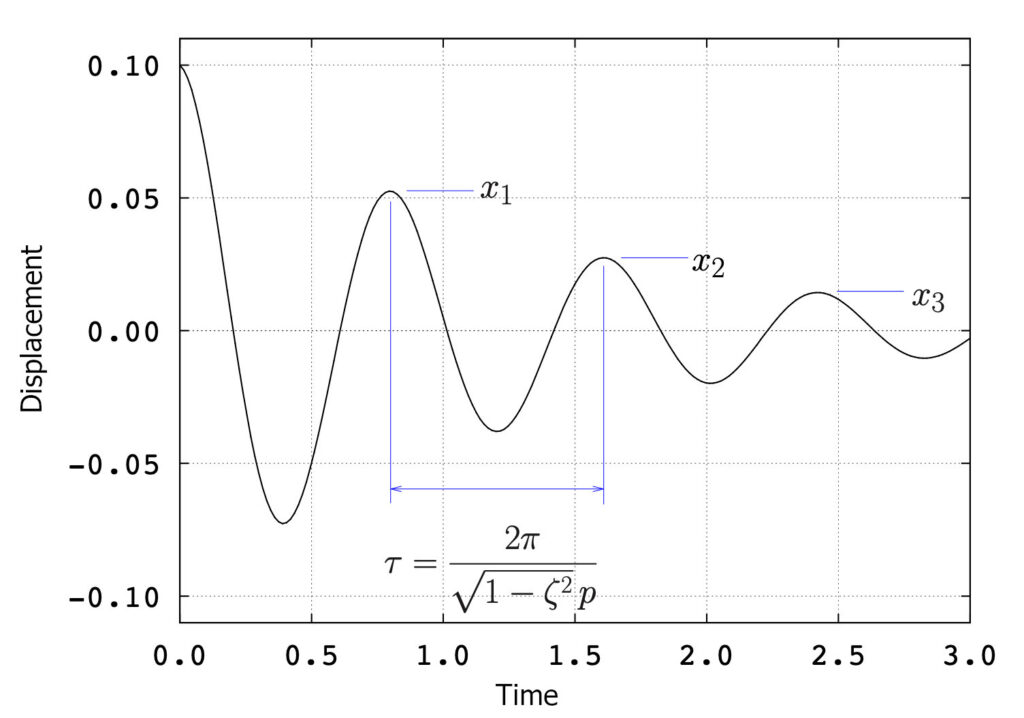

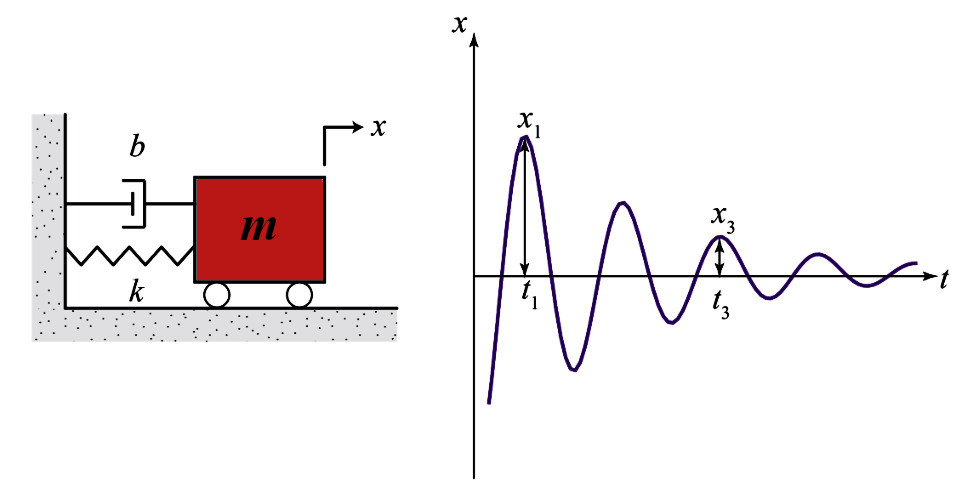

Frequency and Damping: Optimizing Absorption

The effectiveness of vibration absorption depends on a component’s ability to respond to the natural frequency of the machinery. Every mechanical system has a natural frequency, which is the speed at which it vibrates spontaneously. Vibration dampers are designed to counteract this frequency, reducing the amplitude of the oscillations. For example, air springs are ideal for low-frequency vibrations in heavy equipment, such as presses or generators, while cylindrical rubber vibration dampers are more suitable for medium-high frequencies, such as in electric motors.

Types of damping based on frequency:

- Low frequency (<10 Hz): Air springs for heavy machinery.

- Medium-high frequency (10-100 Hz): Rubber or polyurethane vibration dampers.

- High frequency (>100 Hz): Silicone gaskets for precision electronics.

Component Design: Form and Function

The shape of vibration isolators plays a crucial role in their damping effectiveness. Components are designed in specific shapes to suit different loads and applications:

- Cylindrical: Ideal for light, uniform loads, such as in fans.

- Conical: Support heavy loads, common in industrial machinery.

- Bell-shaped: Provide stability for equipment with complex movements. In addition, the combination of materials, such as rubber and metal, increases structural strength, allowing vibration isolators to withstand high loads without losing damping capacity.

Material Properties: Elasticity, Strength, and Durability

Material properties are essential to ensure effective absorption. Elasticity allows components to absorb energy without permanent deformation, while chemical resistance (e.g., to oils or acids) and durability in extreme environments (heat, cold, UV) ensure long-term performance. Materials such as PTFE, due to their low friction, are used in precision applications, while EPDM offers weather resistance for outdoor applications.

Key material properties:

- Elasticity: Absorbs energy without breaking.

- Chemical resistance: Protects against corrosion in aggressive environments.

- Durability: Guarantees consistent performance over time.

In summary, vibration absorption combines materials science and engineering to reduce the impact of oscillations. The choice of suitable components and materials, such as anti-vibration mounts and gaskets, allows for the optimization of machinery efficiency and safety in various industrial contexts.

Materials Used for Vibration Absorption

The choice of materials is essential to ensure effective vibration absorption in industrial applications. Materials with specific properties, such as elasticity, chemical resistance, and durability, are designed to dissipate oscillatory energy and protect machinery and operators. Below, we analyze the main materials used in anti-vibration components, such as those found in a wide industrial catalog, highlighting their characteristics and applications.

Rubber: Versatility and Elasticity

Rubber is one of the most common materials for vibration absorption due to its high elasticity and affordability. Different types of rubber offer specific properties for industrial applications:

- Natural Rubber (NR): With its excellent elasticity, it is ideal for components such as cylindrical anti-vibration mounts used in light machinery, such as fans or pumps. Its ability to deform and return to its original shape effectively absorbs medium-frequency vibrations.

- SBR Rubber: Offers a good balance between cost and mechanical strength, frequently used in automotive applications for engine mounts.

- EPDM rubber: Resistant to atmospheric agents, ozone, and UV rays, it is perfect for outdoor environments, such as agricultural machinery or equipment exposed to the elements.

These rubbers are valued for their ability to reduce noise and wear in industrial and automotive applications.

Neoprene (CR): Strength and Durability

Neoprene (CR) is a viscoelastic material that combines mechanical strength and environmental durability. Its ability to resist UV, oils, and ozone makes it ideal for applications in engine compartments and HVAC systems. For example, neoprene sleeves protect pipes and ducts from vibration, reducing the risk of structural damage. Neoprene is particularly effective due to its versatility in harsh environments, such as marine or industrial environments exposed to adverse weather conditions.

Silicone (VMQ): Performance in Extreme Environments

Silicone (VMQ) is known for its resistance to high temperatures (up to 200°C) and biocompatibility, making it ideal for sectors such as food and medical. Silicone seals, for example, are used in food processing machinery to absorb vibrations without contaminating products. Its elasticity and chemical resistance also make it suitable for precision electronics applications, where vibrations must be minimized to protect sensitive components.

Polyurethane: Strength for Heavy Loads

Polyurethane is a robust material with high abrasion resistance and good elasticity. It is particularly suitable for heavy-duty applications, such as conical vibration dampers for presses or large industrial machinery. Its ability to withstand high loads without permanent deformation makes it an excellent choice for high-stress environments, such as construction sites or production facilities.

Technoplastics: Precision and Chemical Resistance

Technoplastics, such as PTFE, PA6, PE HDPE, and PVC, are used in precision components due to their low friction and chemical resistance. PTFE, in particular, is ideal for gaskets and sealing rings in corrosive environments, such as chemical plants, where it reduces vibration without compromising sealing. PA6 and PE HDPE offer mechanical strength and durability, while PVC is economical and versatile for less demanding applications. These materials are essential for components that require precision and longevity.

FFKM and Viton: Solutions for Aggressive Environments

Materials such as FFKM and Viton are designed to withstand extreme conditions, such as exposure to aggressive chemicals or high temperatures. Viton O-rings, for example, are used in chemical plants to seal and absorb vibrations without degrading. FFKM, with its superior chemical resistance, is ideal for critical applications in sectors such as petrochemicals.

Metal-Rubber Combinations: Structural Stability

Metal and rubber combinations, such as steel or stainless steel with EPDM or neoprene rubber, are used in vibration dampers to provide structural support. These solutions are common in heavy machinery, where rubber absorbs vibrations and metal provides stability, such as in engine or compressor mounts.

In conclusion, the choice of material depends on the specific application, the frequency of vibrations, and the environmental conditions. Materials such as rubber, neoprene, silicone, polyurethane, technoplastics, FFKM, Viton, and metal-rubber combinations offer versatile solutions for vibration absorption, ensuring efficiency and durability in industrial processes.

Download this article in PDF:

Industrial Applications of Vibration Absorption

Vibration absorption is crucial in numerous industrial sectors, where specific components such as anti-vibration mounts, gaskets, couplings, and air springs protect machinery, improve efficiency, and ensure safety. Below, we explore how anti-vibration solutions are applied in different areas, highlighting the role of specialized materials and components in contexts such as automotive, HVAC, manufacturing, aerospace, agriculture, electronics, and maritime.

Automotive Sector: Comfort and Protection

In the automotive sector, vibrations generated by engines and road surfaces can compromise component durability and driver comfort. Rubber vibration dampers (such as those made of NBR or Viton) and O-rings are essential for reducing oscillations in engines, suspensions, and electronic systems. For example, NBR rubber engine mounts absorb high-frequency vibrations, protecting sensitive electronic circuits. Viton O-rings, which are resistant to oils and high temperatures, ensure a tight seal in transmissions while reducing vibrations. These components improve safety and comfort, extending the useful life of vehicles.

Main applications:

- Engine mounts to reduce vibration and noise.

- O-rings to seal and dampen oscillations in hydraulic systems.

- Flexible couplings for smooth and quiet transmission.

HVAC systems: Silence and Efficiency

In heating, ventilation, and air conditioning (HVAC) systems, vibrations from compressors and fans can generate noise and wear in ducts. Rubber gaskets and air springs are ideal solutions for isolating vibrations. Weather-resistant EPDM gaskets protect ducts from vibrations and leaks, while air springs absorb low-frequency vibrations in large compressors. The use of materials such as neoprene in HVAC systems reduces noise, improving comfort in commercial and residential buildings.

Common solutions:

- Air springs for large compressors.

- Neoprene gaskets for silent ducts.

- Cylindrical vibration isolators for fans.

Manufacturing Sector: Precision and Durability

In industrial production, precision machinery such as CNC machines require constant protection from vibrations to ensure accuracy and longevity. Cylindrical and conical vibration dampers made of rubber or polyurethane absorb the oscillations generated by rapid movements or heavy loads. Flexible couplings, such as Giubo or Paguflex, reduce the transmission of vibrations between rotating components, protecting the gears. These components are essential for maintaining precision in high-production environments.

Key components:

- Conical vibration isolators for presses and lathes.

- Paguflex couplings for vibration-free transmissions.

- Rubber mounts for precision machinery.

Aerospace: Reliability in Extreme Conditions

In the aerospace industry, vibrations during flight can compromise the safety and functionality of components. Lightweight and reliable materials, such as silicone gaskets and PTFE sealing rings, are used to absorb vibrations in engines and electronic systems. Silicone resists high temperatures, while PTFE offers low friction and chemical resistance, ideal for extreme environments. These components ensure stable performance during the stresses of takeoff and landing.

Examples of use:

- Silicone gaskets for on-board electronics.

- PTFE rings for aeronautical hydraulic systems.

- Lightweight vibration dampers for turbines.

Agriculture: Outdoor Resistance

Agricultural machinery, such as tractors and combine harvesters, operate in harsh environments, exposed to dust, humidity, and climatic variations. EPDM vibration dampers and neoprene mounts are designed to withstand these conditions, protecting components from vibration and shock. These weather-resistant materials ensure long service life in fields and farms.

Agricultural applications:

- Rubber vibration dampers for tractor suspensions.

- EPDM gaskets for hydraulic pumps.

- Adjustable feet for stable machinery on uneven ground.

Electronics: Protection of Sensitive Components

In the electronics industry, sensitive components such as printed circuit boards require protection from vibrations to prevent malfunctions. Small vibration dampers and adjustable rubber or silicone feet isolate high-frequency vibrations generated by fans or motors. These components, often made of materials such as silicone, ensure stability without adding significant weight.

Electronic solutions:

- Rubber feet for servers and computers.

- Silicone gaskets for sensitive devices.

- Miniature vibration dampers for consumer electronics.

Marine Sector: Resistance to the Marine Environment

In the marine sector, equipment vibrations must be controlled in corrosive environments such as salt water. Neoprene and EPDM seals, which are resistant to salt and UV rays, are used to seal and dampen vibrations in marine engines and pumps. These materials, as reported by Kinsoe, guarantee reliable performance in harsh marine conditions.

Maritime components:

- Neoprene gaskets for marine pumps.

- EPDM vibration dampers for marine engines.

- Vibration-resistant pipe sleeves.

Vibration absorption is essential in every industrial sector, where components such as vibration dampers, gaskets, couplings, and air springs meet specific needs. Materials such as rubber, neoprene, silicone, PTFE, and EPDM offer customized solutions for automotive, HVAC, manufacturing, aerospace, agricultural, electronic, and marine applications, ensuring efficiency, safety, and durability.

Types of Vibration Absorption Components

Anti-vibration components are essential for reducing the impact of vibrations in industrial machinery, ensuring stability, safety, and durability. These devices, designed to meet specific needs, vary in shape, material, and function, adapting to different applications and loads. Below, we explore the main types of components used for vibration control, such as those found in a specialized industrial catalog, highlighting their characteristics and applications.

Anti-Vibration Bushings: Versatility for Every Load

Anti-vibration bushings are designed to absorb vibrations and shocks in a wide range of machinery. Available in different shapes, they adapt to specific loads and frequencies:

- Cylindrical: Ideal for light loads and medium-high frequency vibrations, such as in fans or pumps.

- Conical: Perfect for heavy loads, such as presses or industrial machinery, thanks to their ability to withstand high stresses.

- Bell-shaped: They offer stability for equipment with complex movements, such as generators.

- Spring mounts: Used for low-frequency vibrations in heavy machinery, such as compressors.

These components, often made of rubber or polyurethane, combine elasticity and resistance to ensure effective damping.

Seals and O-rings: Sealing and Damping

Seals and O-rings not only seal joints, but also help reduce vibrations. Materials such as EPDM, Viton, and silicone offer specific properties:

- EPDM: Weather-resistant, ideal for outdoor applications.

- Viton: Perfect for environments with high temperatures and aggressive chemicals, such as chemical plants.

- Silicone: Biocompatible and heat resistant, used in the food and medical sectors.

These components absorb vibrations at the points of contact, protecting surfaces and reducing noise.

Flexible Couplings: Vibration-Free Transmission

Flexible couplings, such as Giubo and Paguflex models, reduce the transmission of vibrations between rotating components, such as drive shafts or gears. Made of elastic materials such as rubber or polyurethane, these couplings:

- Absorb torsional oscillations.

- Protect mechanical systems from wear.

- Improve the smoothness of transmissions, such as in CNC machinery or automotive engines.

Adjustable Feet: Stability and Isolation

Adjustable feet are used to level machinery and isolate it from vibrations. Made of rubber or technoplastics, they offer:

- Height adjustment to adapt to uneven surfaces.

- Isolation from medium-high frequency vibrations, ideal for servers, precision machines, or electronics.

- Easy installation in industrial environments or laboratories.

Air Springs: Low Frequency Damping

Air springs are designed to absorb low frequency vibrations (<10 Hz) in heavy equipment, such as hydraulic presses or generators. They offer:

- High load capacity without sacrificing elasticity.

- Effective isolation in environments with slow and intense oscillations.

- Applications in sectors such as construction and manufacturing.

Sutuco Sleeves: Protection for Pipes

Sutuco sleeves are protective sheaths that reduce vibrations in pipes and ducts. Made of materials such as neoprene or EPDM, they prevent:

- Damage caused by vibrations in hydraulic or pneumatic systems.

- Wear caused by contact with hard surfaces.

- Noise in applications such as HVAC or marine systems.

The variety of anti-vibration components, such as anti-vibration mounts, gaskets, couplings, adjustable feet, air springs, sleeves, and technoplastics, allows you to address vibration challenges in every industrial sector. Choosing the right component depends on frequency, load, and environmental conditions, ensuring efficiency and protection.

How to Choose the Most Suitable Anti-Vibration Solution

Selecting the ideal anti-vibration solution requires careful analysis of the specific needs of the application, considering factors such as frequency, vibration amplitude, and environmental conditions. An accurate choice guarantees operational efficiency, machinery protection, and workplace safety.

Analysis of Vibration Frequency and Amplitude

The first step is to identify the frequency and amplitude of the vibrations generated by the machinery. Low-frequency vibrations (<10 Hz), typical of heavy equipment such as presses or generators, require components such as air springs or conical vibration dampers, designed for high loads. Medium-high frequency vibrations (10-100 Hz), common in electric motors or electronics, are best managed by cylindrical vibration dampers or rubber gaskets. For precision applications, such as in electronics, adjustable silicone feet can effectively isolate high-frequency vibrations (>100 Hz).

Assessment of Environmental Conditions

Operating conditions influence the choice of material. In high-temperature environments (up to 200°C), silicone is ideal due to its heat resistance, while PTFE is perfect for corrosive environments, such as chemical plants, thanks to its chemical resistance and low friction. For outdoor applications, such as agricultural machinery, materials such as EPDM offer protection against UV rays and moisture. In aggressive environments, such as petrochemical plants, Viton or FFKM guarantee durability and performance.

Matching Components and Machinery

The design of the component must match the type of machinery. Conical vibration dampers are suitable for heavy loads, while O-rings combine sealing and damping in hydraulic systems. Flexible couplings, such as Giubo, reduce torsional vibrations in transmissions. The choice of shape and material must be aligned with the load and specific function.

Consultation with Experts

Given the complexity of applications, consulting with experts is essential for customized solutions. An in-depth technical analysis can optimize selection, reducing costs and machine downtime.

Choosing the right anti-vibration solution requires a balance between frequency, environmental conditions, and component design. Materials such as silicone, PTFE, and rubber, combined with components such as anti-vibration mounts and O-rings, offer effective solutions for every industrial need.

Conclusion: The Importance of Vibration Absorption

Vibration absorption is a key element in ensuring efficiency, safety, and durability in industrial processes. Uncontrolled vibrations pose a significant threat: they cause premature wear and tear on machinery, increasing maintenance costs, generate excessive noise, compromising operator comfort, and can create safety hazards, such as structural failures or accidents. The adoption of anti-vibration solutions, such as anti-vibration mounts, gaskets, flexible couplings, and air springs, mitigates these problems, extending the life of equipment, reducing noise, and improving workplace safety.

Download this article in PDF:

The variety of materials available, including rubber, silicone, PTFE, EPDM, and technoplastics such as PA6, allows you to address the specific needs of industries such as automotive, HVAC, aerospace, agriculture, and marine. Each application requires targeted components, selected based on frequency, load, and environmental conditions. Exploring vibration control solutions is essential for optimizing machine performance and reducing operating costs. Investing in anti-vibration technologies is not just a technical choice, but a step towards a more efficient and sustainable industry.